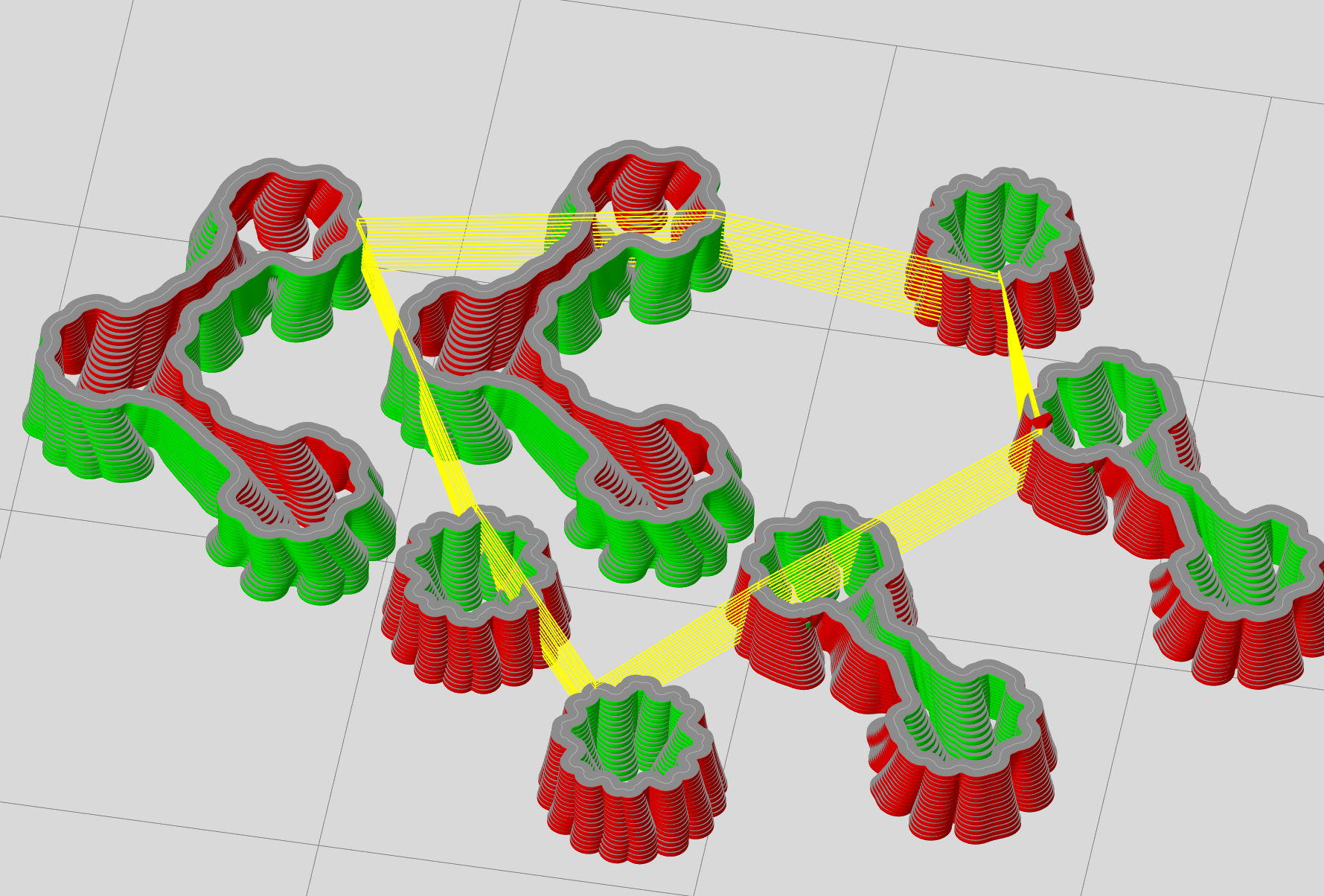

BOD2 BE WILD

Registration Link

Workshop Registration opens September 8th, 2025! Click the link above to be notified when registration becomes available.

Refund and Change Policy

Important: Refund and change requests will not be accepted beyond Monday, October 20th.

Location : UM

Workshop Team

Joaquín Tobar Martínez, Designer

Joaquin is an architectural designer who earned his Bachelor of Architecture from California College of the Arts in San Francisco, and his Masters of Advanced Studies in Digital Fabrication from ETH Zürich, where he published a thesis focused on ceramic assemblies. Currently, he manages the Burdette Keeland, Jr. Design Exploration Lab and teaches parametric design at the University of Houston, where he introduces digital methods and robotic 3D printing. He also conducts lectures and workshops at the ITCA-FEPADE School of Engineering. Previously, Joaquin worked as an architectural designer in New York City and later collaborated with Peri 3D Construction to build the country’s first two-story 3D-concrete printed home.

Workshop Description

How can we adapt structures built with machines within our existing built environment? How can these printed elements blend to create new types of assemblies with reused components?

Collaboration with machines is becoming increasingly common in construction sites. One of the advantages of 3D concrete printing is its ability to create free-form structures without relying on traditional formwork. For this workshop hosted at the ACADIA 2025 Conference, participants will explore the use of COBOD International’s modular gantry system at the University of Miami. Participants will explore topics such as safety guidelines, nozzle design, on-site material mixing, and parametric workflow for g-code generation using the BOD2 printer. This workshop presents a valuable opportunity to apply novel digital workflow while experimenting at a larger scale, generating customized geometries using computational design tools and fabricating in-situ with the support of experts in the field.

Key Learning Outcomes

- Integrate parametric design workflows that generate customized G-code, which will be used with the BOD2 printer

- Provide scenarios in which the new structures can be incorporated into existing architecture that represents a novel way of adaptive reuse. Participants will be asked to incorporate reused building components as part of discrete 3D printed assemblies

Workshop Schedule

Day 1 – Monday, November 3 (9:00 am - 5:30 pm): Introduction and Design

- 9:00 am: Welcome and Introductions

- COBOD BOD 2.0 Intro and Safety Guidelines

- Skill building and parametric workflow

- Design Charrette

- Lunch: 12:30-1:30 pm

- Afternoon: Continue Design Charrette

Day 2 – Tuesday, November 4 (9:00 am - 5:30 pm): Fabrication and Execution

- 9:00 am: Design Charrette continuation

- Geometry slicing

- Printing with COBOD team at University of Miami

- Lunch: 12:30-1:30 pm

- Afternoon: Continue printing and cleanup process

Day 3 – Wednesday, November 5 (9:00 am - 5:00 pm): Exhibition Setup

- Morning: Final touches on prints

- Lunch: 12:30-1:30 pm

- Afternoon: Setup for exhibition

- 5:00 pm: Workshop outcomes presentation

Workshop Location

University of Miami, utilizing COBOD International’s modular gantry system

Prerequisites

- Interest in 3D concrete printing and digital fabrication

- Basic understanding of parametric design workflows

- Willingness to work with large-scale fabrication equipment

Workshop Outcomes

Participants will leave the workshop with:

- Hands-on experience with the COBOD BOD2 printer

- Understanding of parametric workflows for G-code generation

- Knowledge of safety guidelines and on-site material mixing

- Experience incorporating reused building components into 3D printed assemblies

- Practical skills in large-scale 3D concrete printing

- Collaborative project experience in adaptive reuse and digital fabrication