CIRCULAR BRICK: Performative Design for Robotic 3D-Printed Brick using Biomaterials

Registration Link

Workshop Registration opens September 8th, 2025! Click the link above to be notified when registration becomes available.

Refund and Change Policy

Important: Refund and change requests will not be accepted beyond Monday, October 20th.

Location : FIU

Workshop Team

Dinorah Martínez Schulte, MANUFACTURA + University of Florida

Alex Schofield, Co-workshop Leader, California College of the Arts (CCA)

Teri Watson, Co-workshop Leader, FIU Robotics and Digital Fabrication (RDF) Lab

Thank you to Mujeres De Islas for material processing and donation.

Workshop Description

We tend to think of ceramics as an environmentally friendly industry, the reason to make it a popular hobby for many of us. But, is this claim real? Robert Harrison in his book Sustainable Ceramics mentions: “Ceramics with all its necessities for manufacturing, materials, firing, fuels and workspace is certainly not a clean/green environment.” Gas emissions, waste management, transportation and energy consumption are just a few of the characteristics that turn this process into one that negatively impacts our environment.

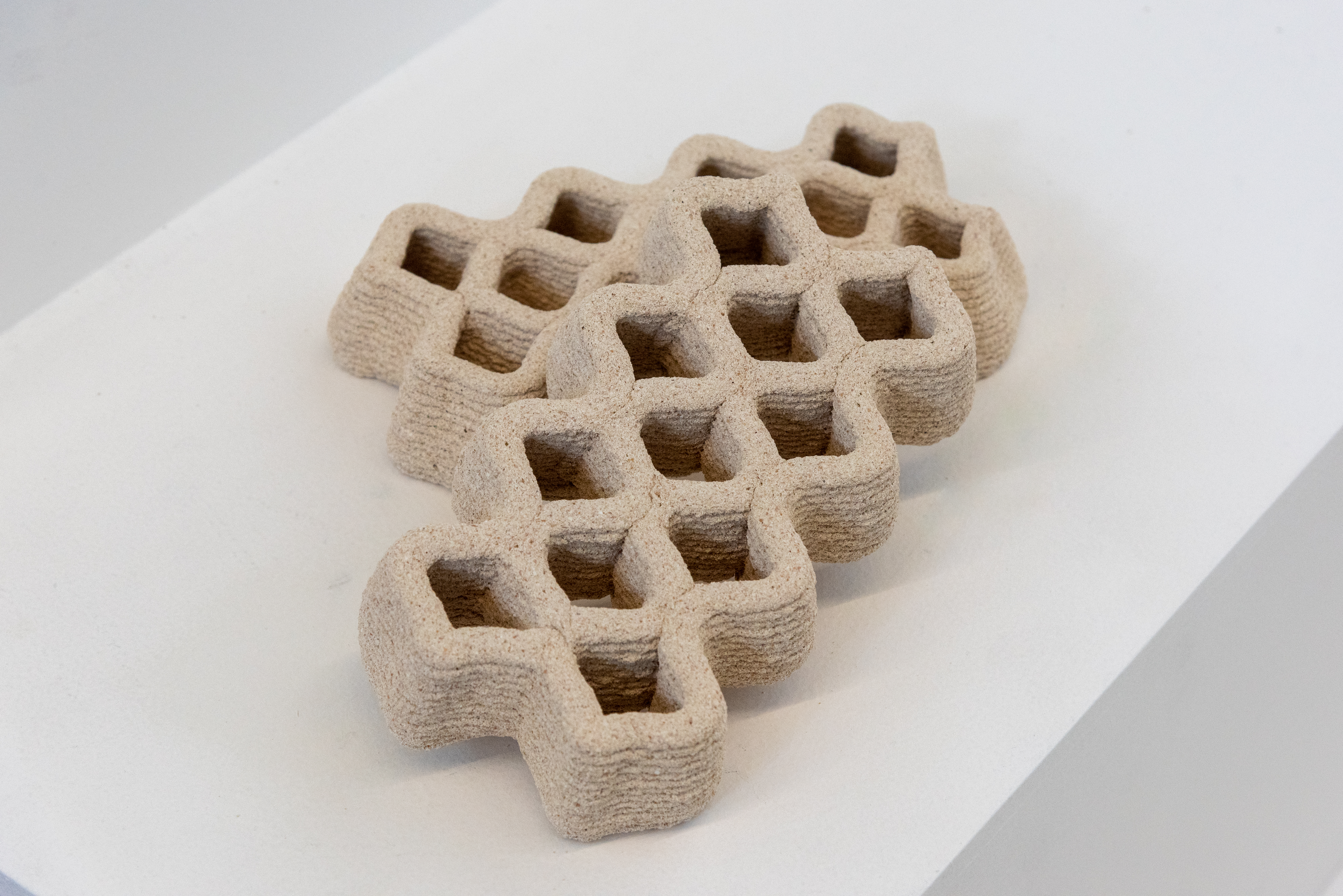

Ceramic today is an often lauded sustainable material alternative to polymers or concrete within the additive manufacturing space. However, we decided to reevaluate the potentials of ceramics, keeping the connection between materiality and nature, extensive access to raw materials, and geometrical freedom and strength. But reducing some of the harmful traits by using locally and biologically sourced binders that allow the mix to solidify without the need of firing. The process is based on 3D printing with a robotic arm - an additive manufacturing process that allows efficient use of material (less waste), geometrical freedom, precision and repeatability.

In this workshop participants will be empowered through education in the emerging territories of alternative bio-based materials intersecting with computational design and robotic fabrication. Participants will learn; about state of the art additive manufacturing at scale, how to prepare bio-based material recipes, how these biod-based ingredients interact with the fabrication process, how to select and apply computational solutions that can respond to the restrictions of the mix, and how to turn the 3D geometry and data into information that can be performed by the robot. Participants will not just be taught a recipe and methodology for application, but more importantly will share skills and perspectives emphasizing the agency of each participant to design and think through materiality. Our objective is to raise awareness about innovation in fabrication processes, sustainable and circular materials, and the necessity to challenge our current processes of manufacture to move towards better ones in the future.

Sargassum and Context

Our bio-based material of focus will be the use of Sargassum, a free-floating brown seaweed, that has long been an important habitat for fish, turtles, and other marine life. However in recent years, it has proliferated at an unprecedented scale across the Caribbean, Gulf of Mexico, and Florida. Once a seasonal and localized phenomenon, massive mats of sargassum now stretch across the Atlantic which form what scientists call the “Great Atlantic Sargassum Belt.” This surge is closely and undeniably linked to anthropogenic impact and climate change: warming ocean temperatures, shifting currents, and increased nutrient runoff from rivers like the Amazon have created conditions that fuel explosive growth.

While sargassum floating at sea supports biodiversity, its arrival on shore has become a major nuisance. Piles of rotting seaweed clog fishing grounds, smother beaches, and disrupt coastal tourism economies. As it decomposes it releases foul-smelling hydrogen sulfide gas, driving away visitors and creating health concerns for coastal communities. Even for fishers, the thick blooms block boat passages and entangle nets which threaten their livelihoods.

The dual identity of sargassum, as both a vital marine habitat and a human hazard, illustrates the complex ecological disruptions of climate change. What was once a natural inhabitant of ocean ecosystems has become, through human-driven environmental shifts, a recurring crisis along the shores reaching the Florida coastline.

This workshop seeks to transform our preconceptions of this material not as a nuisance or waste, but as an opportunity for manufacture. Sargassum, in combination with ceramic compositions, can instead open up a new possibility to create our living in an environmentally responsible way. Application through this process is based on 3D printing with a KUKA KR-150 robotic arm and an extruder, which allows us to shape blocks with different geometries and project them into different architectural applications. Sargassum material has been pre-processed, by drying and pulverizing, and provided through donation by Mujeres De Islas.

Workshop Process

The workshop will begin with an introductory talk, followed by hands-on sessions focused on material preparation and the 3D printing of a scaled prototype brick, designed using Rhino Vault software. Participants will also engage in an introductory exercise on computational design methods to generate the desired forms. The workshop will conclude with an open discussion on findings, insights, and perspectives.

Material Preparation Process

- Dried sargassum will be provided, obtained as waste washed up on the shoreline

- The sargassum is pulverized, to prepare it for introduction to the composition

- The sargassum is measured, then we prepare the mix with ceramic kaolin and other organic binders

- The digital file is prepared, from a Grasshopper file to KUKA SRC, to communicate with the robot

- The composition is mixed with water, until the mixture has a plastic consistency

- Material extrusion tests are carried out with the robotic arm and the extruder to obtain its best physical condition

- The geometry is digitally printed on the robotic arm

- It is left to dry for less than 24 hours to find its final drying

Workshop Schedule

Day 1: Material Development and 3D Modelling by Computational Design

Time: 09:00 - 18:00

- 09:00 - 10:00: Introduction to sargassum, bioceramics, and digital fabrication

- 10:00 - 11:00: Open discussion

- 11:00 - 12:00: Development of the mixture

- 12:00 - 13:00: Lunch break

- 13:00 - 16:00: Rhinoceros + Grasshopper tutorials for 3D modelling for 3D printing

- 16:00 - 17:00: 3D Printing digital paths

- 17:00 - 18:00: Test of final 3D models

- 18:00: End of session

Day 2: Material Mixing and 3D Printing

Time: 09:00 - 18:00

- 09:00 - 11:00: Test of the mix for 3D printing

- 11:00 - 12:00: Design and selection of final architectural items by students

- 12:00 - 13:00: Lunch break

- 13:00 - 15:30: 3D Printing session 01

- 15:30 - 18:00: 3D Printing session 02

- 18:00: End of session

Day 3: Drying Session, Documentation, and Conclusions

Time: 09:00 - 17:00

- 09:00 - 12:00: Final 3D Printing Session and Drying

- 12:00 - 13:00: Lunch break

- 13:00 - 14:00: Clean up and consolidation

- 14:00 - 16:00: Documentation

- 16:00 - 17:00: Conclusions, outcomes, and celebration

Learning Outcomes

In CIRCULAR BRICK: Robotic 3D-Printed Bricks Using Biomaterials, participants will learn the fundamentals of robotic 3D printing with biomaterials. We will explore; material composition and recipes for biomaterials, workflows for extrusion based 3D printing of biomaterials, gcode knowledge and techniques for custom 3D printing toolpaths, and apply computational strategies to adapt designs to the constraints and opportunities of the material and process. By the end of the workshop, participants will be able to print their own modular brick designs. This is not only a technical workshop, but also an open dialogue on the potential of sustainable and innovative practices, particularly within the fields of design, architecture, and the environment.

Required Software and Level

- Software: Rhinoceros 3D and Grasshopper *Those without software knowledge may still sign up for sargassum biomaterial and fabrication experience. Please reach out to 2025@acadia.org for further questions.

- Material: Eggshell donation, limestone and water

- Fabrication Methods: Robotic Arm with clay extruder

Prerequisites

- Basic knowledge in 3D Modelling (Rhinoceros + Grasshopper)

- Basic Knowledge of Rhino Vault by BKR Block Research Group

Workshop Outcomes and Audience

Prototypical Building Elements

Participants will leave the workshop with:

- Individually crafted 3D-printed biomaterial blocks to take ownership of

- A solid understanding of the state of the art in this emerging field of design

- Hands-on experience with material and computational strategies for 3D printing at an architectural scale

- Technical resources to continue their work, including design guidelines and collaboratively developed code

- A network of like-minded peers to exchange knowledge and ideas

Audience

- Audience: This workshop is open to architecture, civil engineering, design, or robotics students of all academic levels, from any institution and language background

- Group Size: Maximum of 10 participants

.jpg)