Forces in Clay: Designing Reef Habitats with 3D Graphic Statics and Clay 3D Printing

Registration Link

Workshop Registration opens September 8th, 2025! Click the link above to be notified when registration becomes available.

Refund and Change Policy

Important: Refund and change requests will not be accepted beyond Monday, October 20th.

Location : FIU

Workshop Team

| Ali Tabatabaie Ghomi, Computational Designer at HKS | LINE, LEED Green Associate |

| Yoana Taseva, Senior Computational Designer at HKS | LINE |

Workshop Description

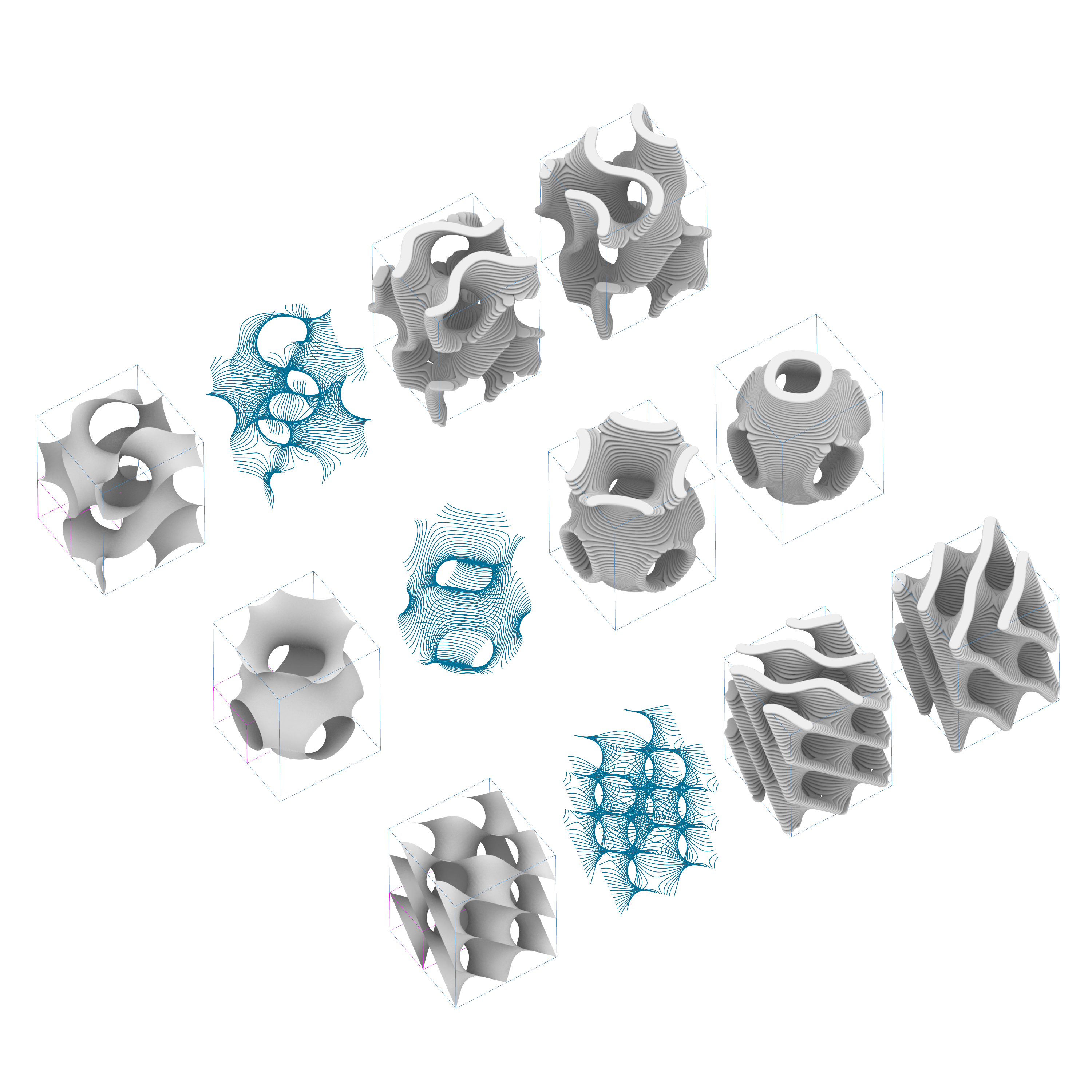

This workshop explores the design and fabrication of coral-inspired, subterranean structures that promote marine ecological regeneration by employing 3D Graphic Statics as a design methodology and clay 3d printing as the fabrication method. Participants will design structurally intelligent, porous, modular geometries that provide costal protection and serve as an artificial reef habitat for coral larvae and other marine life, promoting new coral reef growth. Using computational methods, designs will be generated, analyzed and optimized for clay 3d Printing, culminating in the fabrication of a prototype module.

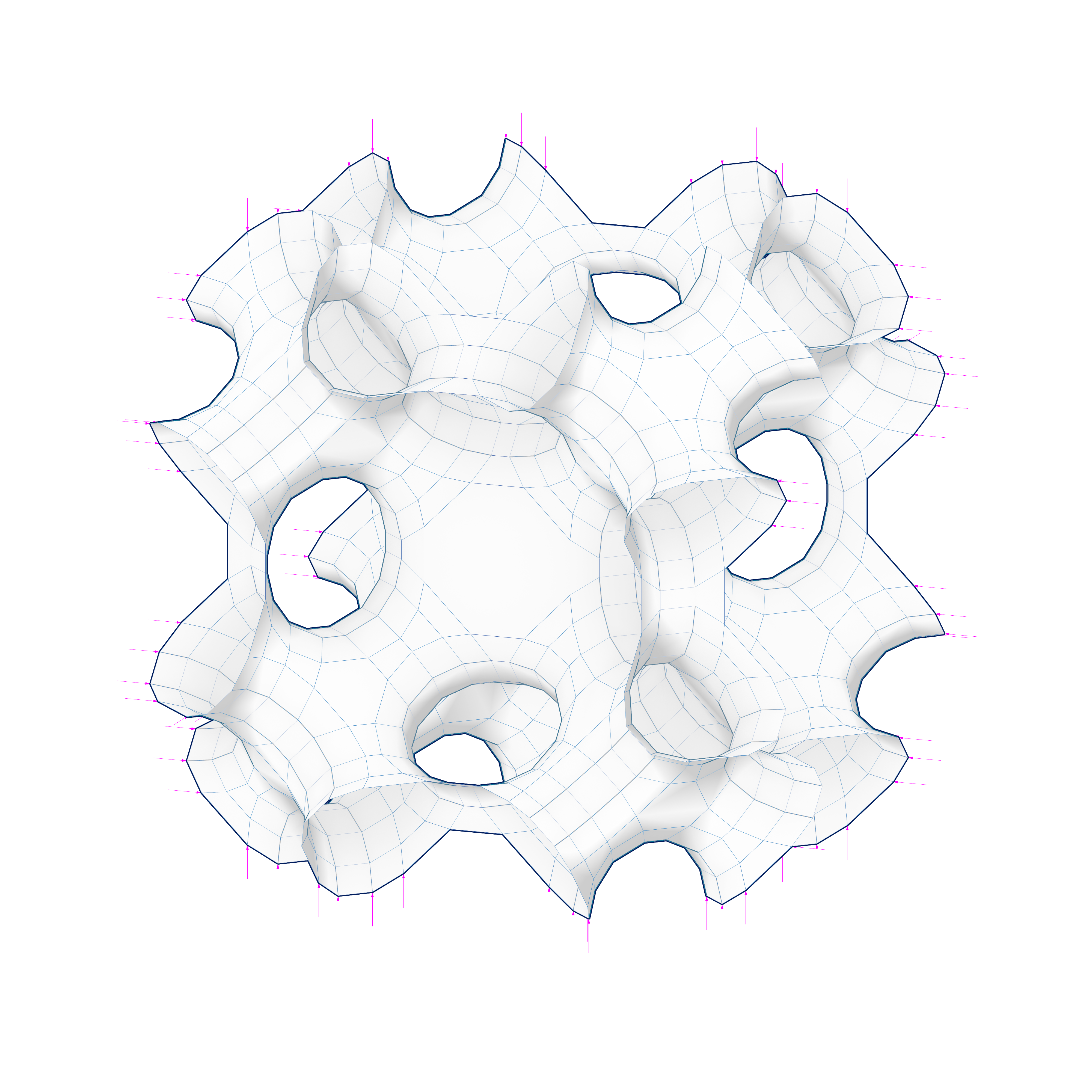

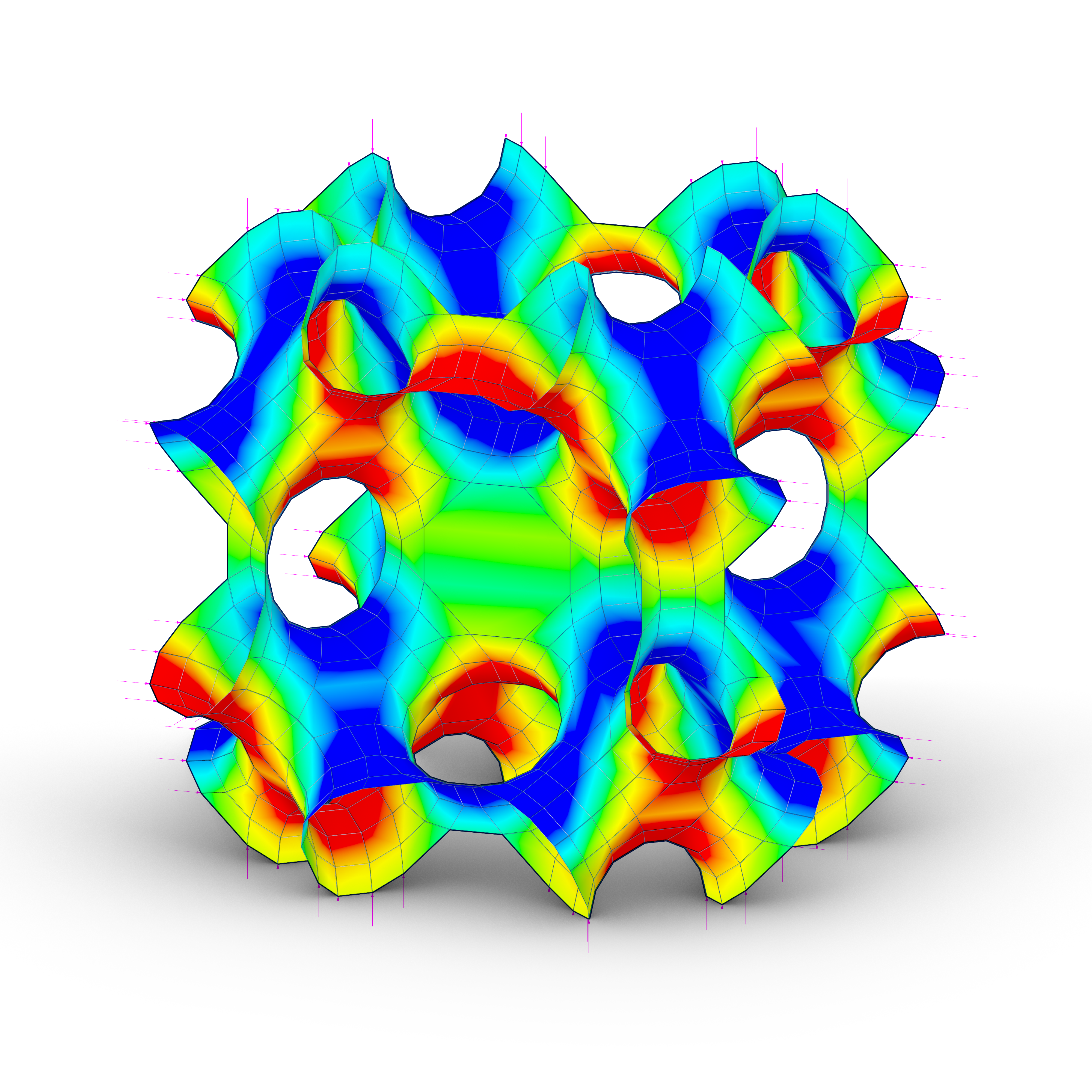

3D Graphic Statics is a geometric approach used for structural optimization and form finding. Recent advancements in parametric and computational tools in 3D Graphic Statics have enabled designers to explore unconventional, complex, and structurally efficient forms. One such example is the geometric generation of Triply periodic minimal surfaces (TPMS) in the form of shellular structures. Their intricate porosity and organic nature make them a great candidate for subterranean structures that support aquatic life in coastal ecosystems under stress, particularly in zones affected by erosion, coral bleaching, and biodiversity loss. However, the geometric complexity of these forms requires novel fabrication methods to minimize time and material cost.

Therefore, we have selected specifically clay 3d printing as the fabrication strategy for this workshop, due to the efficiency and flexibility it provides. By the end of the workshop, participants will have fabricated a series of structural modules that, when assembled, form part of an artificial reef habitat.

By addressing a pressing ecological challenge, this workshop aims to explore and demonstrate how computational design, and digital fabrication can help build an efficient and sustainable environment.

Key Learning Outcomes

In this workshop participants will be introduced to the principals of 3d Graphic Statics and large scale 3d printing. Participants will use the Rhino/Grasshopper plug-in Polyframe2 to design and build spatial structures using shellular geometries. They will analyze the geometry overhangs and optimize the designs for 3d printing. Using a custom Grasshopper script, participants will slice their designs for printing and will integrate a 3d-printed texture to serve as habitat for coral larvae integration and as a last step they will produce custom G-Code files for large scale 3d printing and gain hands on experience in working with 5 axis robot arms and clay extruders.

Workshop Schedule

Duration: 3 days

Number of Participants: 15 (will work in groups of 3)

Day 1 – Monday, Nov. 3 (9:00 am - 5:30 pm): 3D Graphic Statics Form Finding

- 9:00 am: Introduction to 3D Graphic Statics and reciprocal form and force diagrams

- Morning: Introduction to PolyFrame 2 and Shellular structures

- Afternoon: Design a shellular structure module.

- Lunch: 12:30-1:30 pm

Day 2 – Tuesday, Nov. 4 (9:00 am - 5:30 pm): Geometry Optimization for 3D printing

- Morning: Introduction to geometry overhang analysis, mesh optimization for 3d printing

- Lunch: 12:30-1:30 pm

- Afternoon: Generating print path with grasshopper and texture application for coral plug integration.

- Exporting G-Code for clay 3d printing and preparation of test prints

Day 3 – Wednesday, Nov. 5 (9:00 am - 5:00 pm): Fabrication Day

- Morning: 3D Printing and troubleshooting of the final designs.

- Lunch: 12:30-1:30 pm

- Afternoon: Final printing and documentation

- 5:00 pm: Workshop outcomes presentation

Needed Software

- Rhino3d 8

- Polyframe 2: https://www.food4rhino.com/en/app/polyframe-2

- Basic knowledge of Grasshopper and parametric modeling is required.

Instructor Bios

Ali Tabatabaie Ghomi

Ali is a Computational Designer at HKS LINE with focus on computational geometry, design rationalization, digital fabrication and custom tool development. He’s experienced in both AEC industry and academia and is actively working on bridging the two worlds. Prior, Ali was the lead computational designer at CetraRuddy Architecture and a researcher at Polyhedral Structures Laboratory at University of Pennsylvania as well as Advanced Building Construction Laboratory at City College of New York. His research is focused on design methodologies using 3d graphic statics and fabrication of complex spatial structures.

Yoana Taseva

Yoana is a Senior Computational Designer at HKS LINE with a specialization in large scale 3D-printed construction. Her work bridges design and delivery, focusing on geometry-driven workflows, robotic fabrication, and emergent construction methods that bring innovative forms into the built world. Prior to LINE, Yoana was a Senior Design Technologist at ICON, a construction technologies company, which employs 3D-printing robotics, software and advanced materials to shift the paradigm of homebuilding. While there, Yoana co-developed ICON’s concrete wall system, authored algorithmic rulesets for printed wall geometry, and prototyped novel printed features. Prior, Yoana was a Resident Fabricator at the Autodesk Technology Center, Boston and a Scientific Researcher at Digital Building Technologies, Zurich. Yoana holds a Bachelor of Architecture from Cornell University, and a Master of Advanced Studies ETH in Architecture and Digital Fabrication from the Swiss Federal Institute of Technology, Zurich (ETH Zurich).