Print-Scan-Adapt: Feedback-Driven Bead Geometry Control in Pellet Extrusion

Registration Link

Workshop Registration opens September 8th, 2025! Click the link above to be notified when registration becomes available.

Refund and Change Policy

Important: Refund and change requests will not be accepted beyond Monday, October 20th.

Location : FIU

Workshop Team

Aldo Sollazzo, LAMÁQUINA

Hritik Thumar, LAMÁQUINA

Workshop Description

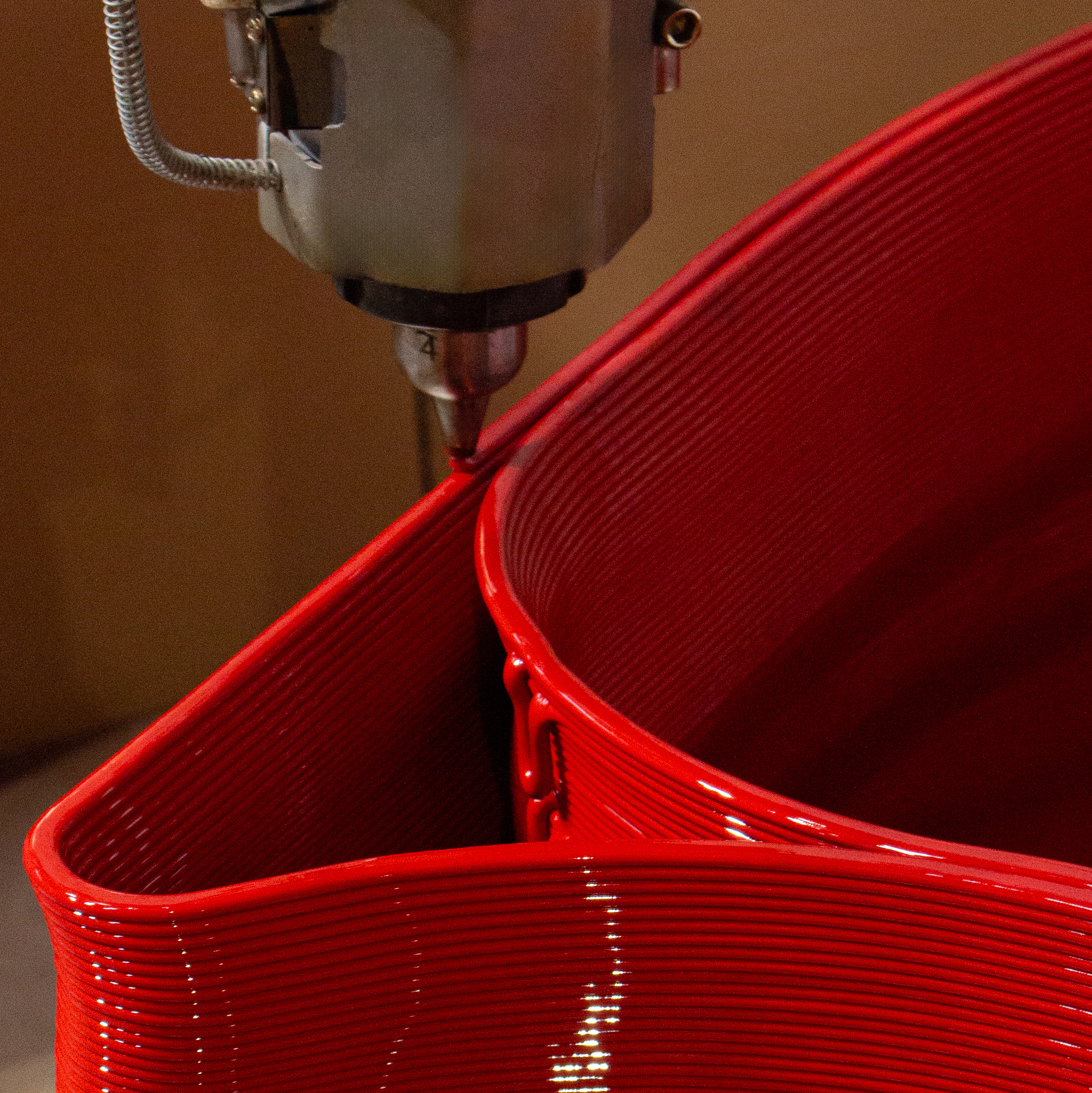

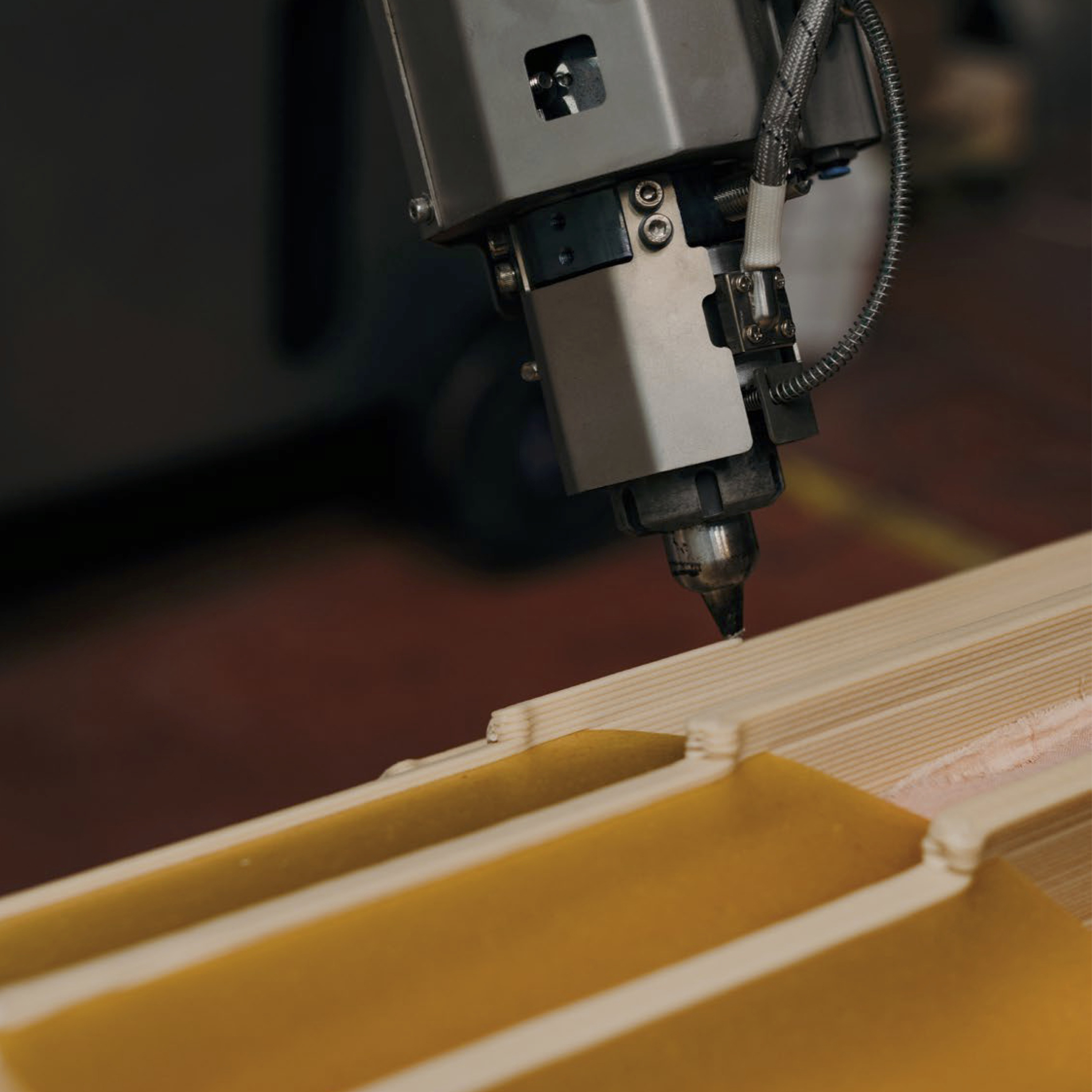

Print–Scan–Adapt is a research-driven workflow developed at LAMÁQUINA that integrates sensing, data analysis, and adaptive control into large-scale 3D printing. Traditional extrusion processes often produce inconsistent results, with bead width and layer accuracy shifting due to speed, acceleration, and material flow. By combining real-time scanning with robotic parameter mapping, this workflow transforms fabrication challenges into data-driven design opportunities.

This workshop brings the research to life in a hands-on format, exploring feedback-driven control in large-scale pellet-based 3D printing. Pellet extrusion offers a sustainable alternative to filament deposition, supporting recycled polymers and industrial-scale output, yet the process is inherently unstable. Participants use a flange-mounted Intel RealSense depth camera to measure bead width during printing, correlating this data with robot speed and extrusion parameters via KUKA|prc. The resulting mapping model predicts and adapts deposition outcomes, allowing participants to actively control material behavior.

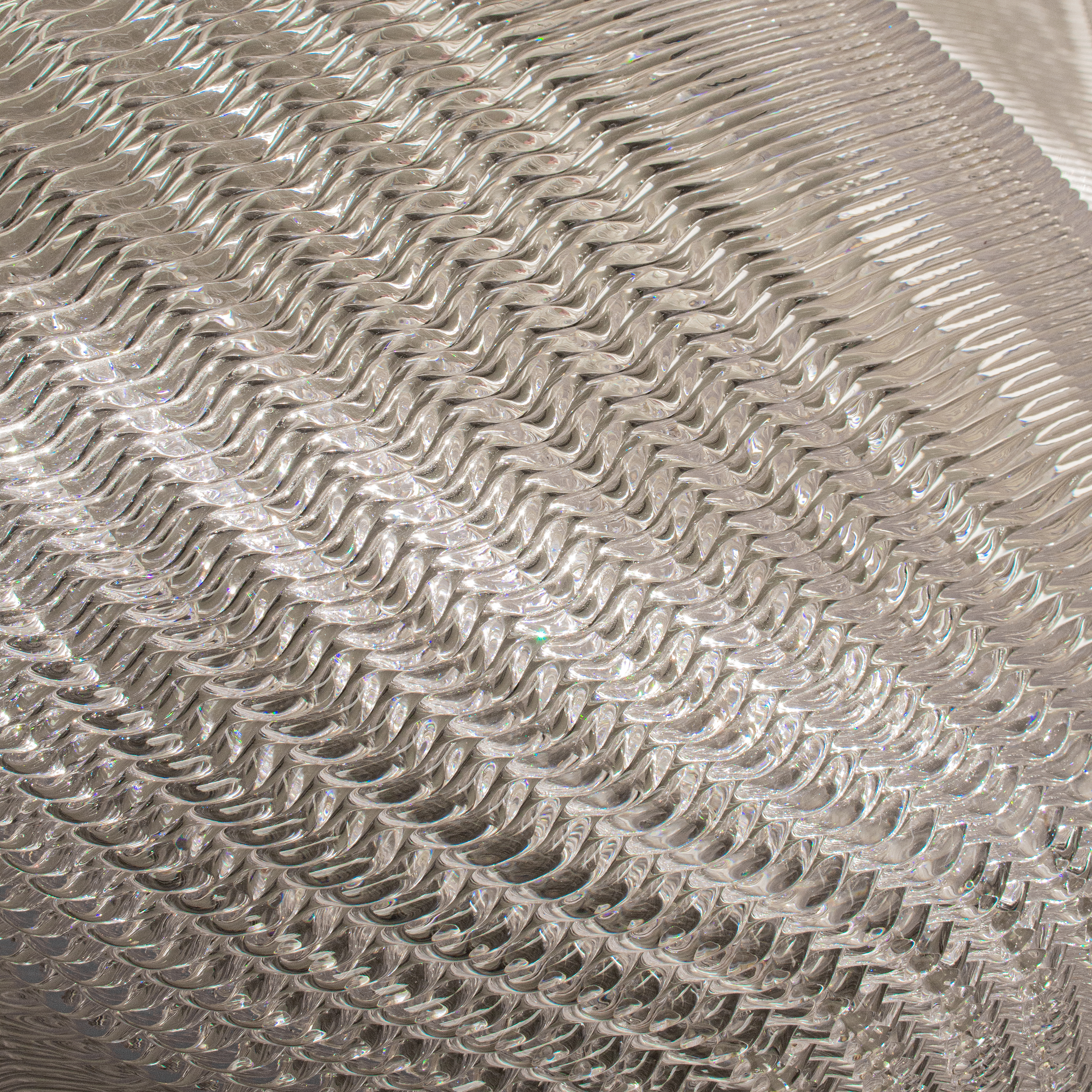

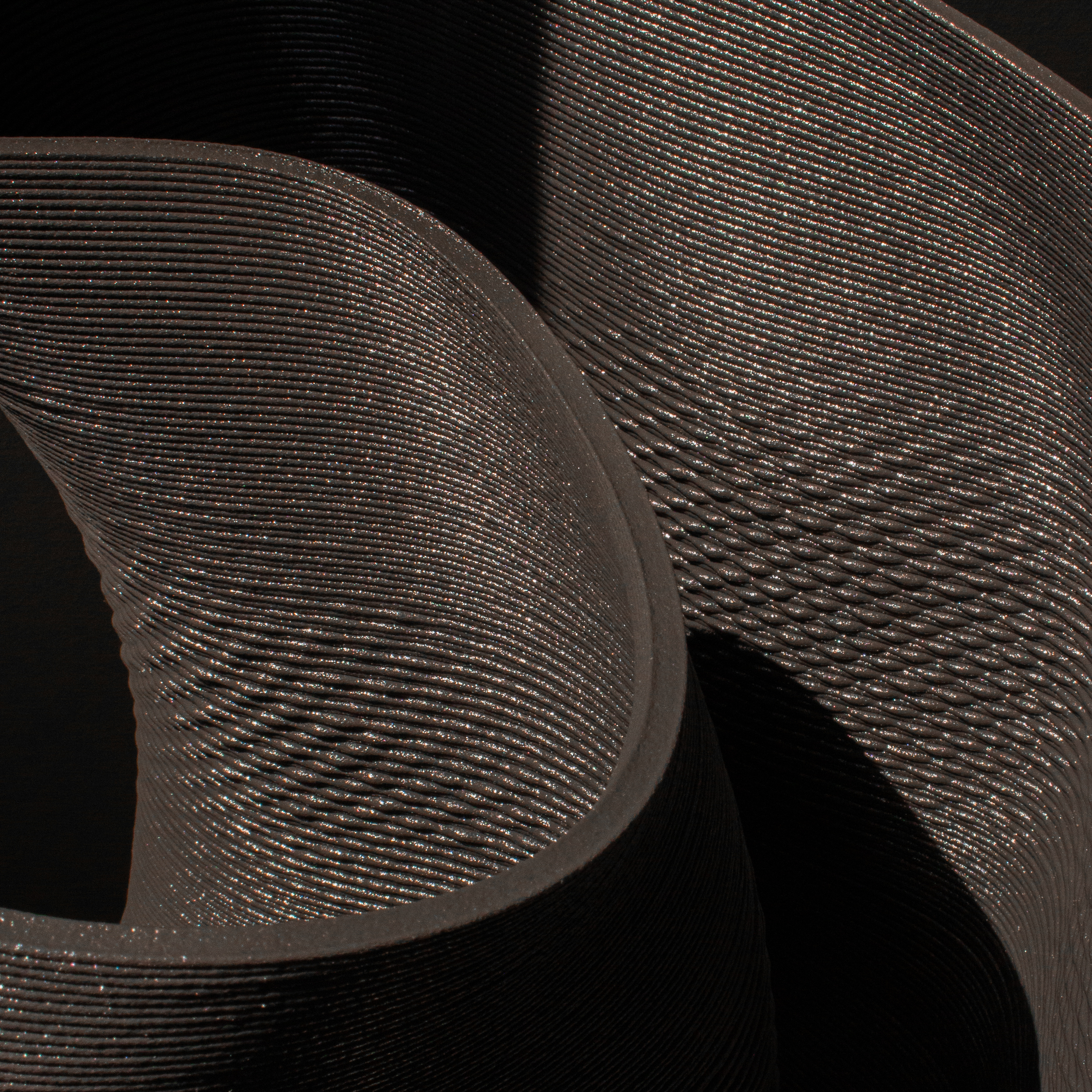

Print–Scan–Adapt emphasizes computation as a tool for resilience at the material-process interface, turning unpredictable extrusion into a design opportunity. By deliberately guiding over- and under-extrusion, participants create patterned modules where material variability becomes an intentional aesthetic. The final outcome is a collective prototype — such as a column or arch — assembled from modules whose surface textures directly reflect the process feedback, demonstrating how sensing, computation, and design converge in large-scale additive fabrication.

Key Learning Outcomes

- Understand Pellet-Based Additive Manufacturing: Identify and analyze the challenges of pellet extrusion, including flow instability, bead width variation, and die swell.

- Integrate Sensing for Real-Time Feedback: Set up and operate a scan-to-feedback workflow using Intel RealSense and Grasshopper, correlating robotic parameters with measured bead geometry.

- Develop Predictive Toolpath Models: Build width-mapping models that translate target bead sizes into adjustable toolpath parameters and control variable deposition as a design element.

- Fabricate Adaptive, Data-Driven Modules: Apply image-sampler logic and adaptive control to produce modules demonstrating material responsiveness and surface variation.

- Collaborate on Collective Assemblies: Contribute to a final prototype that embodies resilience, material intelligence, and computational design.

Workshop Schedule

Day 1 – Calibration & Data Collection

Time: 10:00 am – 5:00 pm (w/ 1-hour break)

- Welcome + overview of ACADIA theme & workshop goals

- Introduction to pellet extrusion and feedback workflows

- Printing test coupons: straight lines, arcs, corners at varying speeds

- Scanning workflow: bead width extraction with RealSense

- Building initial speed vs width dataset

Deliverables:

- Set of calibration prints

- Logged dataset correlating speed with bead width

- Preliminary visualization of width vs. speed graph

Day 2 – Mapping & Design Integration

Time: 10:00 am – 5:00 pm (w/ 1-hour break)

- Developing a mapping function: target width → robot parameters

- Introducing image-sampler logic in Grasshopper

- Designing variable-width toolpaths based on images/patterns

- Pilot printing of patterned strips with scan validation

Deliverables:

- Fitted width-mapping function

- First patterned test strips with visible variation in bead width

- Scan data comparing intended vs. achieved bead geometry

Day 3 – Prototyping & Assembly

Time: 10:00 am – 5:00 pm (w/ 1-hour break)

- Generating toolpaths for final modules (column/arch components)

- Printing with variable-width toolpaths; scanning to validate

- Assembly of modules into collective prototype

- Wrap-up: discussion of resilient workflows, sustainability, and design expression

Deliverables:

- Individual modules printed with intentional bead width variation

- Scans validating controlled over-/under-extrusion

- Collective prototype (assembled column/arch)

- Group reflections on outcomes and future applications

Total Workshop Time: ~21 hours over 3 days

Participant Information

- Audience: Students, researchers, and professionals in architecture, design, and digital fabrication

- Skill Level: Intermediate. Prior knowledge of Rhino/Grasshopper is helpful but not required

- Group Size: 15–20 participants

.jpg)